Platform

Our approach

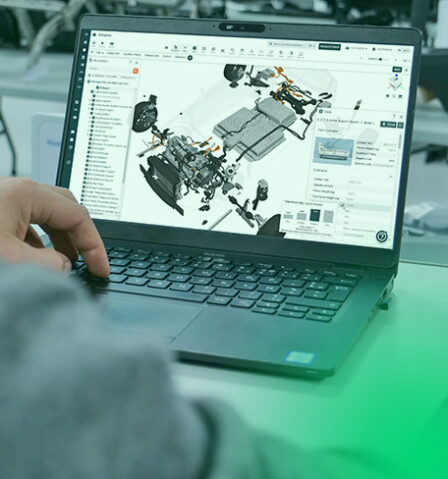

A2MAC1 is offering a cutting-edge and industry-agnostic collaborative benchmarking data management platform, powered by a highly secured cloud computed technology stack featuring a unique user-friendly interface. We provide you with an undisputed software concept to structure, process, and catalyze your precious global benchmarking data. This enables you to reveal the key insights, using advanced comparison features and reporting tools and allows you to share them with users you would like to involve, across multiple departments, locations, and geographies. Being the undisputed global benchmarking leader for more than 25 years, A2MAC1 has built its expertise, tools, and methods into a robust and collaborative benchmarking platform for its customers to turn data into profound insights.

How we impact your business

Our platform integrates, optimizes, and displays data from multiple sources on a centralized, secure platform. This allows you to go faster with better results in generating ideas and savings, as our platform will dramatically increase overall efficiency and thereby reduce your benchmarking budget. You will be able to keep the data protected and organized in a single repository that is fully traceable and includes version control, further enabling cross departmental collaboration. With our collaborative benchmarking platform, we turn your precious benchmarking data into profound insights.

- Consolidate data: Integrate seamlessly from multiple data sources, hosting all your benchmarking data in one centralized, secure platform.

- Optimize data: Get smarter results, faster with an easy-to-use, functional, and flexible database structure offering advanced reporting capabilities. With a fully integrated, comprehensive toolset including 3D data processing and cost data management.

- Generate ideas: Dynamize your creativity by combining digital benchmarking features with virtual collaborative tools.

- Save and gain: Reduce your benchmarking budgets whilst increasing overall efficiency and protecting your competitive data and edge.

Key figures

OEMs & OESs trust our platform

of files processed in our platform

million data points for over 50k products analyzed

users